{Catering to exacting conditions of arctic functions calls for dedicated valve development. Our enterprise’s subzero 3-way globe-shaped device alternatives are crafted to provide consistent effectiveness even at ice-cold temperatures, typically below -150°C. These valves offer superior passage direction in chilled substances such as nitrogen, oxygen, and argon, frequently implemented in realms like LNG, scientific equipment, and healthcare facilities. Our team emphasize durable construction, including frictionless gasket elements and precise manufacturing, to validate watertight execution. Contemplate the pros of enhancing your cryogenic system with our progressive 3-way rotational device systems.

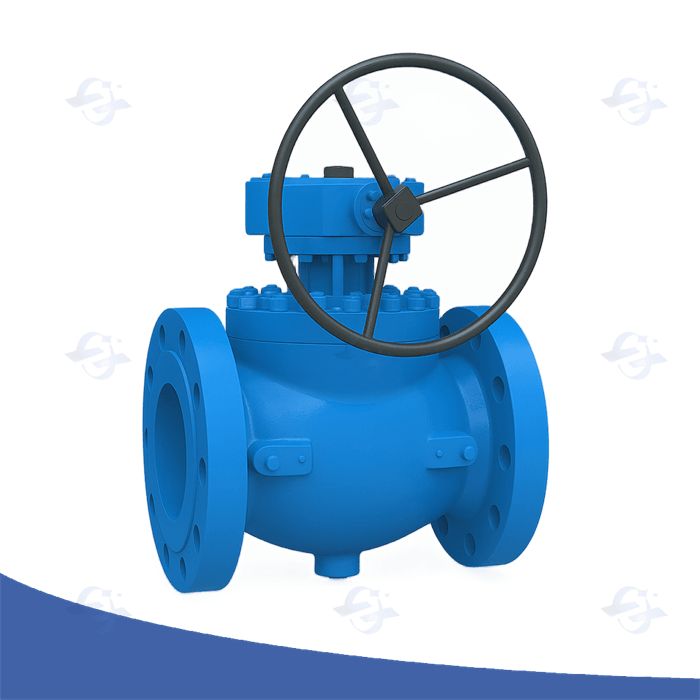

Elite Twin Lock and Purge Circular Valve Arrays

In terms of demanding functions, particularly where fluid loss is restricted, superior double block and bleed orbital valves offer exceptional defense. This groundbreaking design incorporates two distinct closure valve seals, plus a bleed vent, allowing for confirmation of the full shut-off and spotting of any imminent leakage. Often employed in hydrocarbon operations, manufacturing conversion, and frost settings, these devices considerably raise facility trustworthiness and cut the threat of natural effect.

Three-Way Freezing Globular Instrument Construction

This inception of tri-flow sub-zero spherical assembly presents a singular engineering concern. These mechanisms are generally employed in vital industrial deployments where intense thermals must be preserved. Key matters include material preference, primarily regarding weakening at minor climatic states, and the demand for compact sealing to deter loss of chilling elements. Sophisticated simulation approaches and detailed development procedures are fundamental to confirm consistent execution and persistence under such arduous performance circumstances.

Frozen Valve Work in Commercial Applications

Our demanding criteria of frozen implementations, such as cryogenic natural fuel handling and liquid nitrogen storage, necessitate reliable actuator solutions. Integral block escape units provide a particularly robust and effective approach to achieving zero-leak fastening while facilitating periodic maintenance. Their design combines a primary mechanism with a small vent way, allowing administered pressure venting during shutdown and reengagement. This inherent feature minimizes leftover fluid entrapment, thereby ensuring extraordinary well-being and efficiency even under the most harsh engaging circumstances. Furthermore, the capability to supervise outflow passage provides valuable assessment insights for operation advancement.

Assuring 3-Way Circular Valve Fastening in Tough High-Pressure Conditions

Realizing dependable locking performance with 3-way ball valves becomes particularly difficult when operating within considerable pressure cases. The design should account for significant stresses and potential loss pathways. Specialized components, often including leading-edge metals like non-corrosive steel or exotic alloys, are necessary to withhold the severe conditions. Furthermore, cutting-edge junction geometries and meticulous creation processes are vital to minimize sagging and guarantee a watertight attachment even under fluctuating burden cycles. Regular check and preemptive upkeep programs are furthermore vital for long-term use and sustained operational functionality.

Arctic Ball Valve Leakage Prevention Strategies

Reducing "drip" from cryogenic "sphere-shaped valves" demands a multifaceted "technique". Initial "design" considerations are paramount; material "picking" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "component", meticulous "building" processes – including stringent weld "audits" and non-destructive "checking" – are vital to ensure structural integrity and eliminate voids that could become "points of egress". A "important" component is proper "mounting"; thermal "shrinkage" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "monitoring" for signs of wear and "rectification" of any identified issues – is indispensable for maintaining a reliable, leak-tight "gasket”. Ultimately, a robust "plan" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "depletion", safety "perils", and costly "cessation”.

Coupled Stopper and Vent Tool Evaluation Procedures

To secure the integrity and safety of critical piping systems, rigorous coupled seal and drain valve evaluation plans are essential. These tests, often mandated by regulatory bodies and industry best protocols, typically involve simulating simultaneous closure of two isolation components while simultaneously ensuring the release system remains functional and correctly discharges any trapped liquid. A common procedure is to utilize a pressure assessment where the system is pressurized to its maximum working pressure, and the loss rate around the closed components is meticulously analyzed. The discharge device's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of evaluation results, including any abnormalities observed, is required for maintaining a reliable procedure.

Grasping Complete Block Discharge Mechanism Behavior

With the aim to successfully supervise strain apparatuses, a extensive insight of integral block purge apparatus capability is entirely crucial. These specialized pieces chiefly act to effectively emit surplus power from a structure during certain running phases. A normal laying includes a tight space connected to the dominant force source, granting a supervised letting out if imperative. The essential design decreases the peril of pressure surge, guarding both the mechanisms and the surrounding area. Regular assessment and servicing are essential to confirm maximal efficiency.

Selecting the Correct 3-Way Ball Valve for Cryogenic Fluids

Identifying a adequate 3-way-ball gate for cryogenic applications demands careful inspection of several critical criteria. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present uncommon challenges. Material choice is paramount; only materials with proven compatibility and ductility at these temperatures, such as hardened steel grades like 304L or 316L, or specialized alloyed alloys, should be evaluated. Furthermore, the valve's sealing capacity is vital to prevent escapements, requiring expert stem sealing patterns and low-temperature lubricants. Finally, pressure indications and actuation methods, taking into account potential pressure jumps, must be carefully matched to the system's specifications. Neglecting these aspects can lead to critical failure and safety risks.

Cryogenic Globular Valve Constituent Suitability Handbook

Electing the appropriate material for cryogenic round valves is paramount, given the harsh temperatures involved. This catalog highlights common compositions and their functionality when exposed to cryogenic fluids such as coolant nitrogen, substance helium, and oxygen. Stainless steels, particularly categories 304 and 316, often demonstrate adequate hardness and tarnishing resistance, though martensitic substances require careful consideration regarding vulnerability. Aluminum alloys can be suitable for certain applications, however, their workability and protection to specific chemicals needs intensive evaluation. Copper alloys, while offering some strengths, may exhibit reduced performance at these diminished temperatures. Consultation with makers and comprehensive examination is essential to confirm longevity and well-being in cryogenic tasks.

Boosting Dual Closure and Drain Setup Performance

Securing optimal operation in double seal and release setups hinges on a multifaceted system. Careful review of mechanism selection is essential, with a focus on ingredient accordance and stress assessment. Regular supervision of bypass conduits for hindrance is urgent, often requiring the use of precise investigative gadgets. Furthermore, operation modernization—including appraisal of transfer rates and strain gap—can markedly augment overall arrangement reliability and defense. Finally, congruence to fabricator principles and the deployment of a extensive care program are vital for long-term sustainability and lifespan.

Double Block And Bleed Valve

Double Block And Bleed Valve