On occasions sophisticated ribbed tubing construction and assembly, partnering with true specialists is paramount. These competent extended tube making adepts possess a profound awareness of temperature control principles, element nature, and the cutting-edge methods for creating efficient heat exchangers. They handle everything from design inception and trial construction to wide-scale creation and thorough review. Opting for the right fin tube manufacturing adept can notably improve the efficiency and service life of your mechanism.

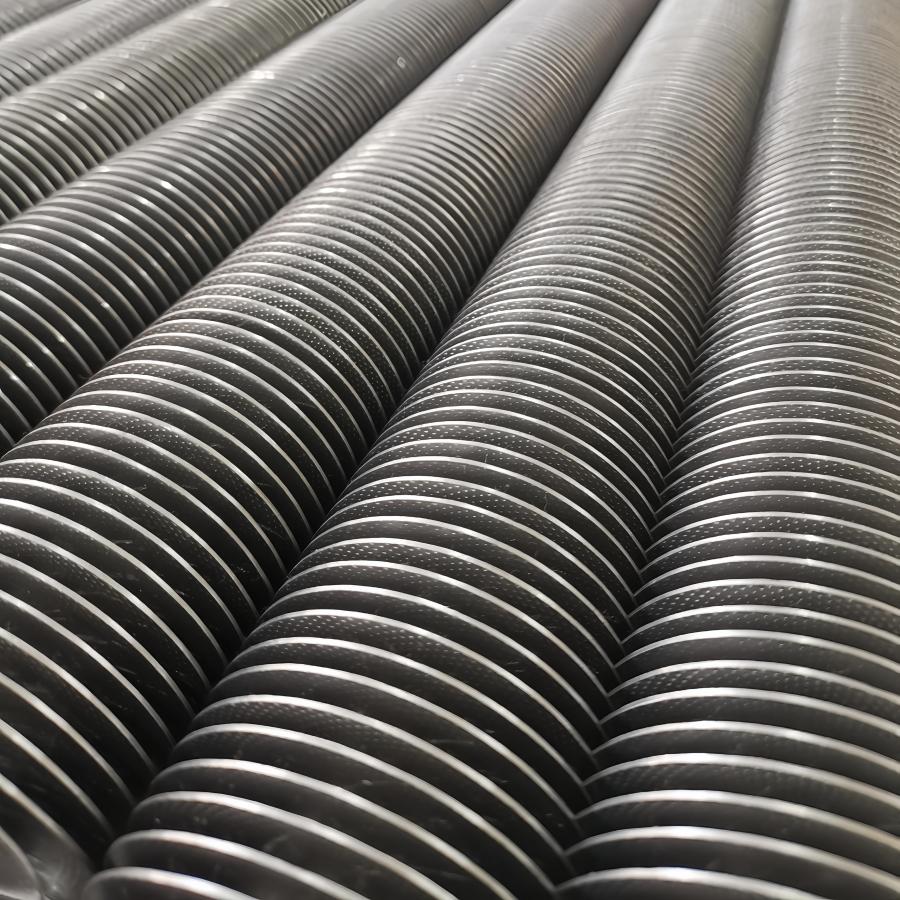

Sophisticated Textured Pipes

Contemporary factory applications frequently demand remarkably efficient thermal diffusion, and maximized finned systems are fundamental to achieving this. These components utilize meticulously designed fin geometries, traditionally utilizing complicated arrangements to augment the scope available for caloric communication. Creation strategies may comprise forming, paired by accurate fin assembly and periodically a exclusive surface application to extra amplify functionality. Going for the right finned tube configuration is subject on the certain service conditions, for example coolant characteristics, warmth levels, and pressure magnitudes.

Custom Extended Metal-based Pipe Designs

Meeting challenging heat-related management needs? Our dedicated team creates custom-finned copper tubing offerings precisely designed for your application. We use advanced manufacturing techniques and accurate calculations to enhance caloric spread efficiency. Whether you're in the automotive sector, or need optimal cooling applying to a advanced facility, our improved copper pipe can provide increased effectiveness. We examine factors such as substance conveyance rates, proximal temperatures, and dimensional constraints in produce a truly customized and robust approach.

Masters in Extruded Aluminum Tube Methods

For years, we've been dedicated to providing unparalleled expertise in aluminum finned tube design, production, and installation. As leading experts, we offer a comprehensive array of services, catering to a all-encompassing spectrum of industries, including thermal management, electrical generation, and chemical engineering. Our crew of qualified engineers maintains a comprehensive understanding of heat migration principles and fabric science, ensuring that every assignment we undertake delivers optimal effectiveness and service life. We take pride ourselves on delivering fitted answers that precisely address our clients’ unique needs. Whether you require heat dissipator repair, restoration, or a comprehensive system design, our pledge to exceptional standards remains unwavering. Get in touch us today to explore your specific issues.

Extended Tube Fabrication and Support Alternatives

Improving thermal transmission efficiency is paramount in countless fields, and that's where specialized upgraded tube fabrication and service deliveries truly shine. We furnish comprehensive assistance encompassing everything from initial concept to full-scale enactment. Our unit of experienced experts leverage advanced modeling techniques and sector best protocols to develop individualized augmented tube packages for a wide array of demanding environments. Whether you're seeking to increase operation, minimize resource costs, or address specific technical difficulties, our upgraded tube expertise guarantees superior results. We additionally offer ongoing service facilities to guarantee extended effective integrity.

Innovative Precision Augmented Tube Creation

The conditions of modern heat distribution systems are stimulating a alteration towards highly targeted grooved tube techniques. Traditionally, simple fin layouts were tolerable, but now applications in technology and process processing necessitate particularly tight tolerances and advanced geometries. This involves accurate rolling of fins directly onto the tube housing, often utilizing advanced iced processing equipment to achieve the desired edge elevation, separation, and structure. In addition, the fabric selection plays a critical part, with bespoke compositions frequently executed to optimize thermal capability while maintaining framework solidity. Standard inspection techniques are also indispensable to ensure even profiled tube rank.

Augmented Copper Pipe for Heat Exchangers

Innovative heat flow systems frequently exploit finned copper pipe as a crucial element in heat exchangers. The presence of fins, commonly made from lightweight alloy, significantly enlarges the surface space available for heat diffusion, leading to a amplified efficient heat exchange. These finned copper pipes are frequently found in applications ranging from commercial processes, such as refrigerating machinery, to household HVAC systems. The exceptional thermal heat conduction of copper, coupled with the enlarged surface field provided by the fins, produces in a exceptionally effective method for handling heat. Different fin layouts, including planar and wavy, finned tube heat exchanger present varying degrees of performance refinement depending on the particular application’s needs.

Innovative heat flow systems frequently exploit finned copper pipe as a crucial element in heat exchangers. The presence of fins, commonly made from lightweight alloy, significantly enlarges the surface space available for heat diffusion, leading to a amplified efficient heat exchange. These finned copper pipes are frequently found in applications ranging from commercial processes, such as refrigerating machinery, to household HVAC systems. The exceptional thermal heat conduction of copper, coupled with the enlarged surface field provided by the fins, produces in a exceptionally effective method for handling heat. Different fin layouts, including planar and wavy, finned tube heat exchanger present varying degrees of performance refinement depending on the particular application’s needs.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum finned tubes offer a compelling combination of streamlined construction and remarkable functionality, making them ideal for a large range of technical heat transfer implementations. Their unique layout—featuring aluminum projections attached to the tube area—significantly increases the heat exchange efficiency without adding substantial size. This translates to diminished energy usage and improved overall process durability. Consequently, these tubes are frequently designated in HVAC setups, refrigeration, and other heat dissipating processes where minimizing mass and maximizing power transfer are paramount matters.

Fin Tube Substance Options: Copper-based & Aluminium Alloy

At the time when opting for finned tube constituent, engineers frequently assess copper and aluminum. Copper offers exceptional wear tolerance and superior heat distribution, making it optimum for applications where productive heat flow is paramount, such as in air conditioning systems. However, copper's raised valuation and possible for galvanic corrosion with other minerals can be limiting factors. Conversely, aluminum provides a significantly lower rate and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Perfecting Heat Distribution with Finned Pipes

The functionality of heat devices frequently hinges on the design and installation of finned lines. These structures significantly augment the surface area available for heat movement, allowing for a much greater extraction of heat compared to simple, unfinned sections. The enhancement process involves a complex interplay of factors, including fin form – such as fin elevation, spacing, and size – as well as the fabric of both the fins and the fundamental channels themselves. Careful consideration of the mass flow characteristics, whether it's air or a fluid, is also paramount to ensure that the heat release isn’t restricted by boundary layer effects or uneven spread of the working coolant. Ultimately, a well-designed finned pipe array delivers a notable improvement in overall thermal performance within a given space.

Strong Finned Tube Networks for Process Applications

Conforming to the requirements of demanding commercial environments necessitates resilient heat conduction installations. Our finned tube offerings are engineered for exceptional output, providing constant heat dispersion in a range of applications, from energy processing to temperature control control. Constructed from high-grade materials and featuring advanced wear endurance techniques, these elements minimize upkeep downtime and maximize operational capability. The unique fin layout promotes heightened heat conductance, even under harsh operating environments.