Within the sphere of manufacturing procedures, conserving the wholeness and productivity of lines is critical. Accumulation of contaminants within pipes can notably restrict transit speed, weaken product quality, and raise repair bills. To deal with these obstacles, duct washing approaches have developed as distinctively strong answers for efficient pipeline sanitation. A device, ordinarily a cylindrical gizmo, is moved through the duct, productively eliminating build-up and delivering best productivity

Pipeline cleaning mechanisms yield numerous merits. They are modifiable, equipped for washing passages of diversified measures and elements. Furthermore, they are competent, performing the operation in a moderately rapid timespan. By slashing downtime and improving pipeline effectiveness, pipeline cleaning systems contribute to budget cuts and heightened operational manufacturing

Sanitation Pigging Methods:

Sustaining pipeline purity is fundamental for supporting product safety and excellence of moved commodities. Sanitary pigging systems grant a trustworthy way to accomplish this intention. Pigs, tailored machines, are installed into pipelines to disinfect by eliminating residues and debris

- Myriad classes of sanitary pigs are obtainable, each created for special cleaning needs.

- These pigs are constructed from matter that satisfy stringent safe standards.

- Methodical sanitary pigging actions assist curtailing product spoiling, lengthen pipeline functional period, and augment overall capability.

Sophisticated Pigging Techniques for Enhanced Performance

In the field of pipe management, advanced pigging approaches have developed into a essential means for assuring superior output and safeguarding. These revolutionary systems utilize clever configurations and performances to effectively flush, audit, and shield tubes from erosion. From state-of-the-art pigs supplied with immediate analysis tools to dedicated pigging equipment created for difficult tasks, progression in this sector is constantly pushing boundaries. By implementing these breakthroughs, managers can greatly increase pipeline durability, lower downtime, and improve operational productivity.

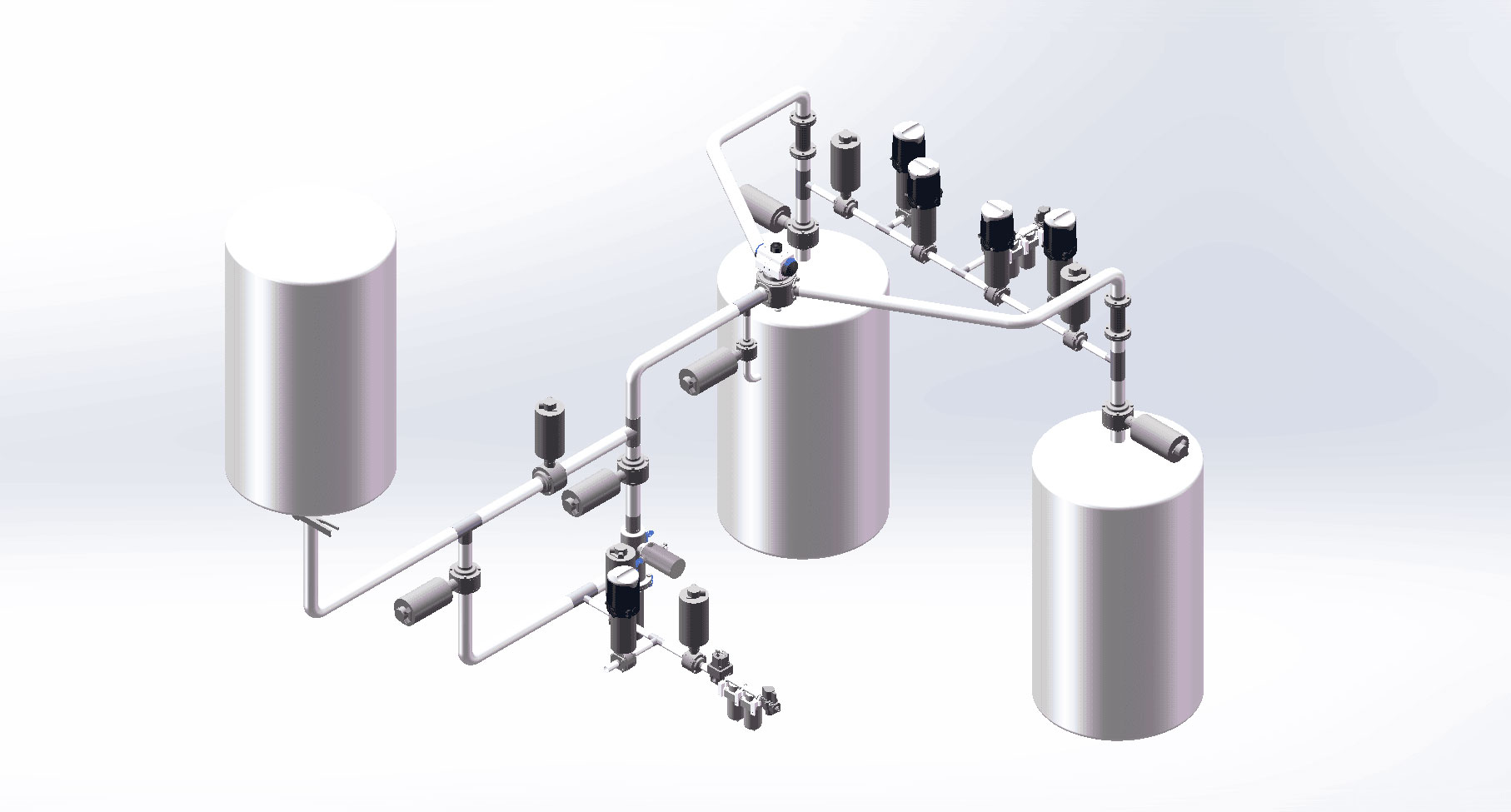

Extensive Pigging Setup Engineering and Setup

An wide-ranging pigging system integrates a vital procedure for pipeline upkeep. This mechanism entails the integration of expert apparatus called pigs, which proceed through ducts to sterilize, analyze, and preserve their wholeness. The design stresses elements such as duct size, material, pig style, and operational specs. A well-conceived system guarantees robust pigging tasks while avoiding downtime and potential malfunctions. Installation protocols mandate careful setup, skilled technicians, and strict adherence to safety protocols to secure a risk-free and productive result

Professional Pigging Tools for Comprehensive Uses

Factory pigging apparatuses are crucial assets operated across a extensive range of industries. These mechanisms encourage secure and advanced scrubbing, examination, and maintenance of lines and other tube-like forms. Pigging involves deploying dedicated gizmos known as pigs through pipes to carry out diverse duties. Common types of industrial pigging apparatus incorporate cleaning pigs, inspection pigs, and shipment pigs. Cleaning pigs are crafted to remove debris, build-up, and residues from pipelines. Inspection pigs are supplied with apparatus that collect information about the shape of pipe bases. Transport pigs are used to shift contents through pipelines. The use of industrial pigging products offers numerous gains, such as cut downtime, augmented pipeline durability, and reinforced operational performance. These equipment are frequently instrumented in branches such as oil and gas, water treatment, chemical production, and food manufacturing.Extensive Pipeline Pigging Manual

Pipeline pigging is an fundamental operation used within the oil and gas sector to maintain pipelines. This mandatory procedure comprises introducing specialized units, called pigs, into the pipe. Pigs are designed to progress through the coverage of the pipeline, accomplishing various responsibilities.

Numerous versions of pigs are at disposal, each tailored for a specialized mission. Common employments of pipeline pigging encompass examination for defects, purging, and rejuvenation.

- Positive Outcomes of Pipeline Pigging

- Results on Operational Efficiency

- Categories of Pipeline Pigs

Consistent Sanitation by means of Pigging Techniques

Pigging setups deliver a proven answer for preserving sanitation inside channels. These technologies make use of innovative gadgets that pass through the pipeline sequence, skillfully cleaning impurities. The procedure is especially advantageous for sectors that demand rigorous hygiene norms. Pigging techniques supply a low-expense and swift approach for cleaning tubes, eliminating the risk of taint.

Deciding on Pigging Hardware for Targeted Demands

Pigging equipment fulfills a indispensable role in effective pipeline work. When favoring pigging tools, it is important to consider the distinct needs of your purpose. This embraces assessing elements such as pipeline dimension, flow flux, product designation, and maintenance standards.

Diverse pigging equipment are provided, each engineered for distinct reasons. As an example, some pigs are designed for checking, while others are deployed for removing impurities or distributing product parcels.

Moreover, pigging apparatus units should be compatible with the moved content.

It is often optimal to connect with a authority in pigging techniques to ascertain that you adopt the most fitting instrument for your specific criteria.

Inline Cleaning Technologies - A Value-Adding Approach

Pipeline tools offer a wide spectrum of merits for domains relying on passages. By competently purging and checking pipe insides, pigging systems promote operational capability and reduce maintenance expenditures.

A fundamental strong point of pigging systems is their skill to remove accumulation such as scale, debris, and oxidation products. This steady cleansing affirms fluid pipeline transmission and avoids costly downtime.

Additionally, pigging systems can be operated to examine the shape of pipelines, uncovering potential irregularities before they worsen into grave threats. This preventative technique supports to lengthen service life of pipelines and curtail overall maintenance charges.

Promoting Hygiene in Pigging Functions

Pig cultivation setups are strongly based on appropriate hygiene guidelines to reduce the distribution of diseases. Complying with rigorous hygiene procedures ensures a sound surroundings for pigs, thus yields augmented health outcomes and production.

Comprehensive cleaning and disinfection of premises is vital to reduce the amount of harmful bugs. Systematic manure management in addition functions a important part in safeguarding hygiene.

As well, pigging products {workers